Responsible Supply Chain

Sustainable Supply Management Hierarchy

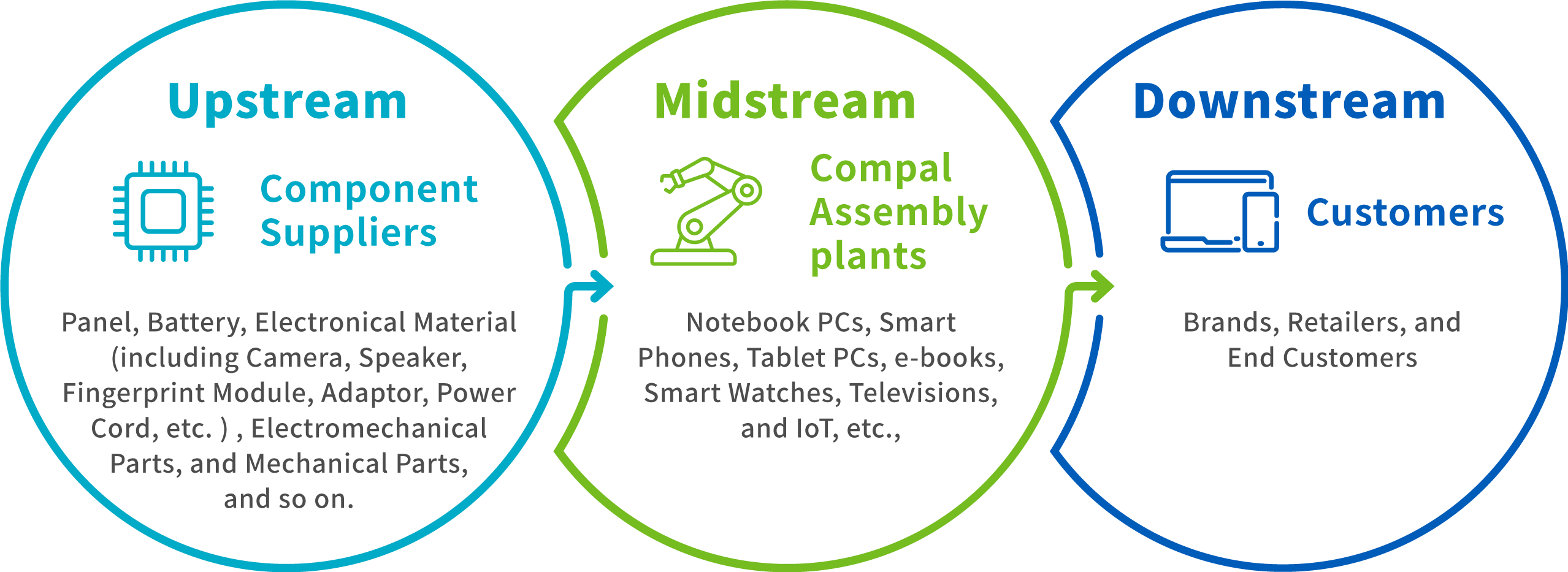

Compal Industry Supply Chain

Products Compal developed include notebook PCs, smart phones, tablet PCs, e-books, smart watches, televisions, and IoT, etc., and also include hundreds of related important components like faceplates, touch screens, camera modules, fingerprint recognition modules, batteries, battery chargers, charger cables, electronic parts and components, electromechanical components (printed circuit boards, flexible print circuits, acoustic components, etc.), and mechanism elements.

Distribution of Supplier Production Regions

Compal is promoting local procurement to improve production and supply efficiency for raw materials, support the local economy and reduce carbon emissions from the transportation process. Local suppliers are being mentored to strengthen the local supply chain, improve inhouse manufacturing, and reduce dependence on overseas procurement. The majority of suppliers are located in Compal’s key production region such as Taipei Headquarters, production bases in Sichuan and along the coast in Eastern China, and northern Vietnam. In 2023,the local procurement ratio was 74% Taiwan plants, 62% for China plants, 13% for Vietnam plants, and 55% overall for all Compal production locations. The distribution of supplier production locations is also calculated based on the number of suppliers, as shown in the table below:

Supplier Classification

Compal suppliers are distributed across the world and involve a complex range of materials. Suppliers are classified by transaction mode, purchasing amount, and existing inherent sustainability risk standards or high risk for the effective management of ESG issues. As a responsible purchaser, Compal’s sustainable supply chain topics are managed according to the following definitions.

Note 1: Please refer to the section on “Supplier Risk Management”for criteria on high risk. High-risk suppliers included one Non-Tier-1 key supplier. Tier-1 Significant Suppliers included 129 Tier-1 Suppliers and 1 Non-Tier-1 Supplier

Note 2: RBA commitment document is titled “Letter Of Undertaking For Compliance With Responsible Business Alliance(RBA) By Vendor”. The CMRT commitment document is titled “Declaration On The Non-Use Of Conflict Minerals”.

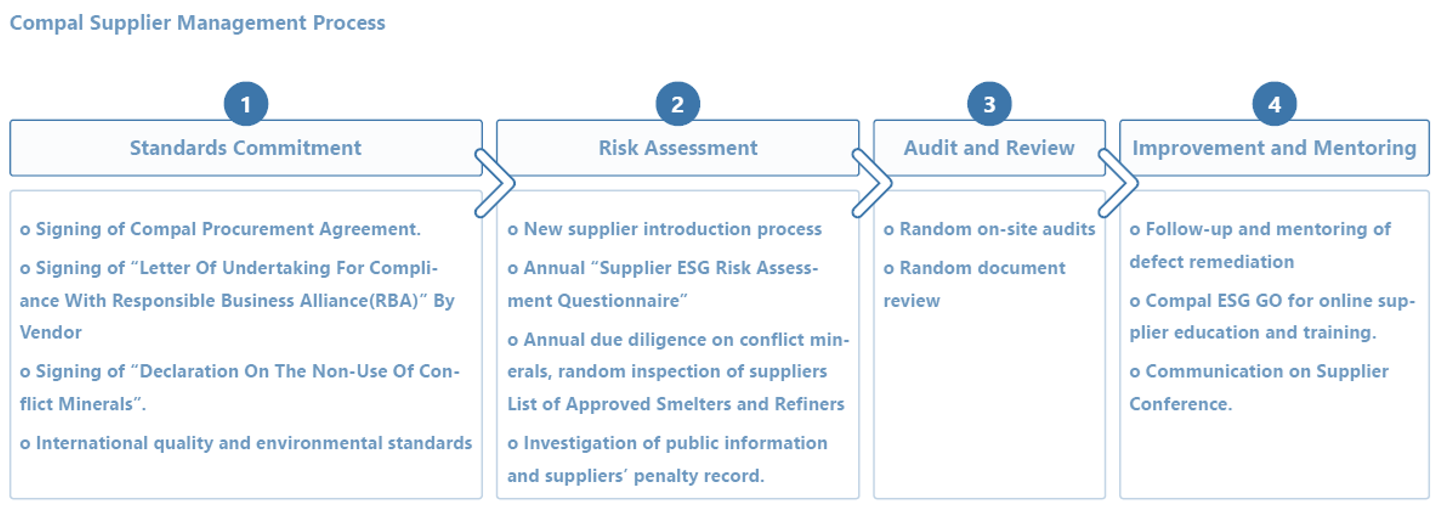

Compal Supplier Management System

As one of the key members of global computers and peripheral equipment industry and RBA member, Compal values sustainable supply chain management significantly and ensures to provide products and services complying with the requirements of ethics, environment and human rights to customers. We have incorporated international sustainability standard to improve the sustainable supply chain management efficiency. With regard to the procurement operation, new suppliers are requested to sign the “Compal Purchase Agreement” before engagement in cooperation and transactions. According to different product types, we also request suppliers to comply with relevant international quality and environmental regulations, and the E, S, G performance is also considered during the supplier selection process. Topics such as GHG, water resource, and waste gaining growing global traction. The corresponding ISO standards have therefore been incorporated by Compal into supply chain management.

Compal regularly conducts education and training on sustainable supply chain topics for purchasing employees as well. External consultation resources are periodically used to keep employees up to date on the latest trends in supply chain management as well as enhance their ability to communicate

sustainability topics and ESG performance to suppliers. As international sustainability topics continue to pick up pace, we invited suppliers to follow Compal’s example and philosophy. We also strengthened our communication of ESG-related knowledge and strengthened our sustainable procurement ability to take a joint interest in environmental, labor, health, and safety-related social issues. We are continuing to improve supply chain resilience through the abovementioned actions.

Note: RBA Code of Conduct: http://www.responsiblebusiness.org/code-of-conduct/

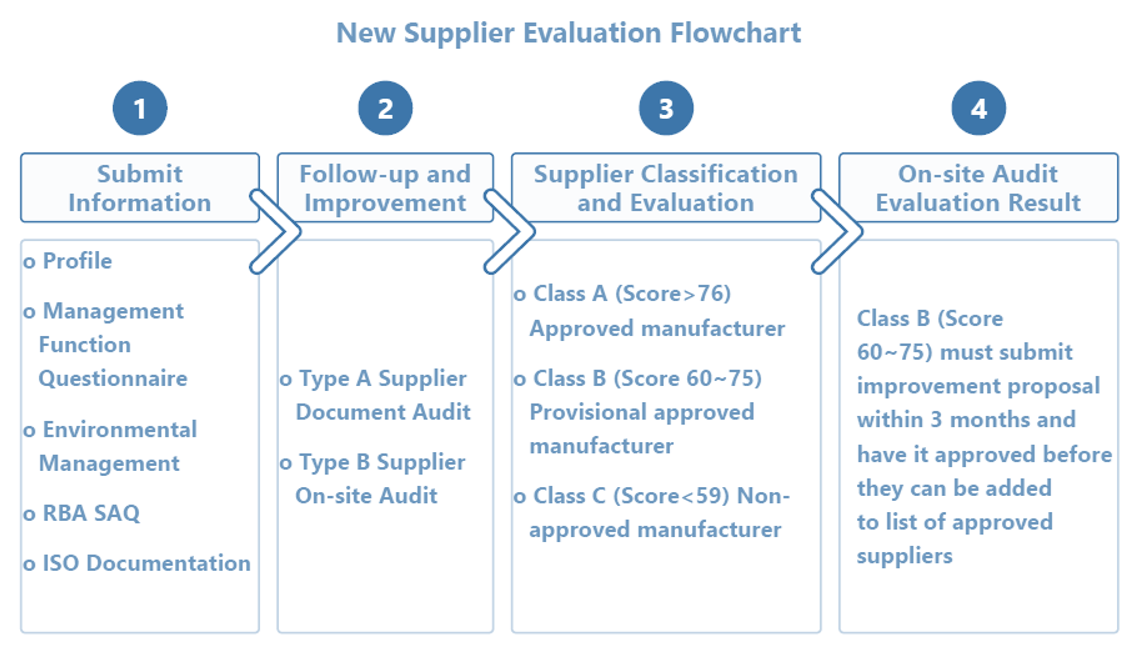

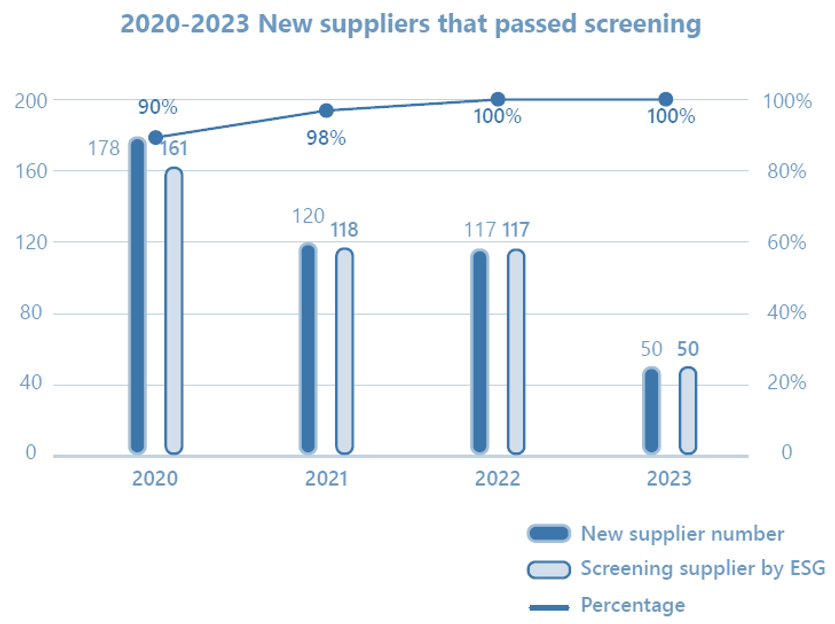

The sustainability performance and record of suppliers can indirectly affect Compal’s reputation or interests. To reduce potential risk, we engage in proactive screening for risk reduction when potential new suppliers are being assessed. Assessment factors include ESG, business performance, country, industry background, and product correlation. If there is a major international event, the regions, industries, and sources of supply involved are also investigated and studied to ensure the stability and continuity of the supply chain, and to protect the Company’s reputation and interests.

The number of new Compal suppliers gradually declined between 2020 and 2023,dropping from 178 to 50. The screening of new suppliers has become stricter and more cautious. A new Supplier Relationship Form was added in 2023 to investigate suppliers’ operating status and product correlation. Questions regarding the country in which the factories are located was also added to the “Supplier ESG Risk Assessment Survey”to help prevent supply chain disruptions during major international events.

Note: Type A Suppliers: 1. Leading Vendor 2. IC Design 3. Customer specified Type B Suppliers: Manufacturers that must be audited by the relevant units.

Compal establish relevant ESG criteria for suppliers, incorporating supplier ESG performance into evaluations. Non-ESG evaluation weight accounts for 81%, while ESG evaluation weight accounts for 19%. Environmental factors include environmental management and policies, and waste management; social factors include occupational safety and health; governance factors include business strategy, information security protection, and supplier selection etc. Procurement, RD, SQE, and other relevant units form an investigation team to conduct on-site, document, or other types of audits for the supplier. A list of suppliers with a rating of (score over 75) or higher must compiled and a report made before it can be added to the Qualified Suppliers List. Suppliers with a B rating (score between 60 ~ 75) will be tracked by rating unit for improvement reports, with improvement reports submitted to Compal’s relevant departments. If a supplier is still unable to achieve grade “A” after improvements are made, they are added to the list of annual assessments. Suppliers receiving a “C” grade will also be directly disqualified. Contracting process will be complete only after each department evaluate all the criteria.

The SAQ self-assessment questionnaire was designed by Compal using the RBA Code of Conduct as its reference to investigate supplier performance in the labor, health and safety, environment, code of ethics, and management system aspects. This year, SAQ was combined with the SASB questionnaire and renamed “Supplier ESG Risk Assessment Survey.” The suppliers of the PC Business Group (PCBG) and Smart Devices Business Group (SDBG) were also merged for risk assessment. RBA SAQ, VAP, Non-VAP or CMA equivalent audit reports specified by the customer can also be used in the place of Compal’s SAQ. A total of 937 vendors were assessed in 2023. The investigation scope covers Tier-1 suppliers and non-Tier-1 critical suppliers representing 80% of transaction amounts. Survey recovery rate was 99%. If a supplier did not cooperate on responding to the survey, the relevant unit will be notified to revoke their approved supplier status.

2023Supplier ESG risk assessment questionaire and signing of RBA Commitment Letter: Suppliers Investigated count 937 companies, Completion Rate 99%

Supplier ESG Risk Assessment Questionaire questions as classified into major, ordinary, or minor issues. Violations of major issues or compliance in the supplier survey are used to classify a supplier as high, moderate, or low-risk. Existing risk assessment content including exposure by government or NGO, employee intensity, use of hazardous chemicals or radioactive substances, production of toxic and restricted waste, production of industrial effluent, and production of industrial emissions. Management corresponding to each level of risk is then carried out. Those that violate more than 5 major issues or answer correctly less than 65% of the questions are classified as highrisk suppliers and added to the audit list. Risk analysis of the 2023 survey identified 42 high-risk suppliers for further management. These will undergo document/on-site audits and counseling by Compal’s audit unit or a third-party to ensure supplier compliance with Compal ESG standards and to reduce the level of risk. In terms of supply risk, whenever a major international disaster occurs, Compal immediately conducts a disaster investigation of key suppliers in the affected region. The severity of impact to supplier is established and the corresponding measures adopted to ensure business continuity. If there is a change in national policy, suppliers are investigated by Compal as well to ensure compliance with national regulations and that there will be no interruption to supply.